Stone Crusher Plant

Complete set of stone crusher plant is composed of jaw crusher(coarse crushing), impact crusher(fine crushing), circular vibrating screen and belt conveyor. According to different technological requirements, the stone crusher plant can be configured with appropriate types of equipment so as to play the best performance.

Email: info@sinoftm.com ( We will contact with you in 15 minutes)- Overview

- Technical data

The stone crusher plant can be applied to the aggregate production of hard limestone, pebble, gravel, granite, basalt, calcite, sandstone, cement clinker, glass, quartz, concrete, dolomite, bluestone, iron ore, coal gangue, construction waste, metallurgical slag, artificial sand, etc, in water and electricity, building materials, expressway, urban construction and other industries.

It has high automaton level, low operation cost, high crushing efficiency, energy conservation, high production capacity(50-800TPH), low pollution, easy maintenance, etc. The stone produced by stone crushing plant can completely accord with national standard, which has good grain shape, even granularity and reasonable grading.

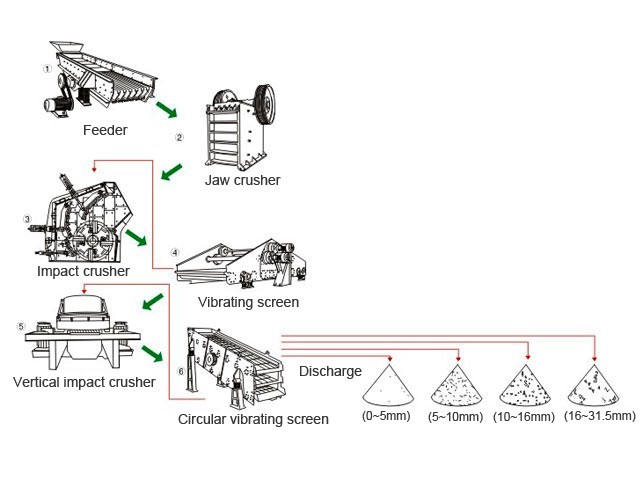

Process of Stone Crusher Plant

Firstly, raw materials are sent to jaw crusher for primary crushing, then the produced coarse materials are sent to impact crusher through belt conveyor for further crushing. The finely crushed stone enters vibrating screen and screens out of three kinds of stone with different sizes. And the extraordinary large stone will be back to impact crusher for again crushing.

Application of Stone Crusher Plant

This stone production line is especially suitable for producing and processing highway surface material, high grade highway pavement gravel, gravel aggregate of high-speed railway passenger dedicated line, sandstone of hydropower station, stone in port, pier and airport pavement, and other special construction fields. Meanwhile, the rock crushing plant can be configured with different machines to satisfy different requirements of customers.

Advantages of Stone Crusher Plant

1. Simple and Easy Operation. It has advanced electric control operating system that has high automation level. The whole production line is of simple process and easy operation, which is without manual operation in addition to startup, shutdown and routine maintenance of machines.

2. High Quality of Finished Products. The stone crusher plant has solved the fatal problem of unqualified grain shape of traditional equipment, which has high quality of finished stone, uniform granularity, good grain shape, less stone powder, etc. Fote stone crusher plant complete comply with national highway materials requirements.

3. High Economic Benefits. It overcomes the disadvantage of high production cost caused by serious abrasion of traditional equipment when crushing and processing hard materials, which has high output and production efficiency, low operation cost and high economic benefits.

Related Production Line

What Can I Do For You?

You can also send a message to us by this email info@sinoftm.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!

What Can I Do For You?

You can also send a message to us by this email info@sinoftm.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!