Mineral Powder Dryer

Mineral powder dryer can be used to dry coke, raw scrap iron, copper concentrate, silicon carbide powder, rare earth ore,mercury powder, tin powder, cobalt ore, nickel ore, manganese ore powder, gold ore powder, steel slag, water slag and other materials.

Email: info@sinoftm.com ( We will contact with you in 15 minutes)- Overview

- Technical data

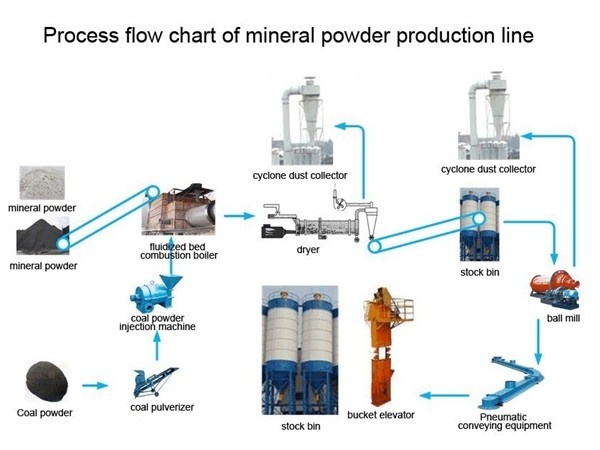

Mineral powder dryer is a new-type and professional drying machine composed of heat source, scatterdevice, belt feeding machine, feeding machine, rotary drum, belt dischargingmachine, induced draft fan, discharger and power distribution cabinet.

There are many types of mineral powder dryers according to the raw material: manganese mineral powder dryer, nickel mineralpowder dryer, mercury mineral powderdryer, gold ore powder dryer and tin mineral powder dryer, etc.

It makes many technical innovations in the lifting device system and adopts new-type composite device, overcoming the "wind tunnel" phenomenon of the traditional dryers. It has high thermal efficiency and can reduce coal consumption by 20% or so. Mineral powder dryer is suitable for many kinds of combustion chambers: high temperaturefurnace in fluid bed, the grinding powder coal furnace and artificial coalstove. The big and small transmission gears adopt substituted pin column gearinstead of traditional steel wheel, saving a lot of investment, maintenance cost and maintenance time.

Features of Mineral Powder Dryer

1. Mineral powder dryer adopts anadvanced drying process: high temperatureandrapiddryingprocess,which has a big heat transfer coefficient, high heat efficiency and largedrying strength.

2. Combining the high-speed mixing drying and airflow drying together could scatter the viscous materials apartfully and expand the contact area between materials and heat medium. This can speed up the drying process.

3. Mineral Powder Dryer adopts aspecial scraping device which could avoid material viscosity to the cylinderwall.

4. It has wide application fields, simple operation, small amount of maintenance and stable product quality.

5. Mineral Powder Dryer, professionally designed to dry ore powder, is adjustable in the angle of rotatingblade and rotary speed of revolving shaft.

6. Mineral Powder Dryer is equipped with reflux layer for rather wet materials in the upper part of themachine, while airflow dryer is equipped with special mixer.

Related Products

What Can I Do For You?

You can also send a message to us by this email info@sinoftm.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!

What Can I Do For You?

You can also send a message to us by this email info@sinoftm.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!