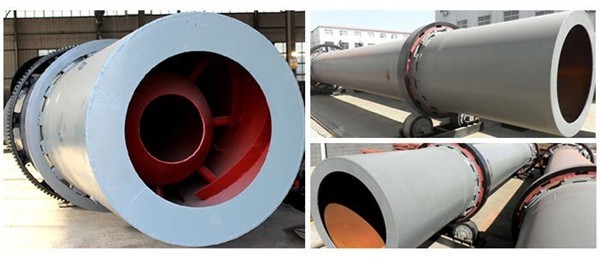

Indirect Heat Dryer

The indirect heat dryer or indirect heat transfer dryer, as a type of dryer, is widely applied to dry materials like slag, limestone, coal powder, slag and clay in the building material, metallurgy, chemistry and cement industry.

Email: info@sinoftm.com ( We will contact with you in 15 minutes)- Overview

- Technical data

The indirect heat dryer uses indirect heat transfer method, which makes no direct contact between hot air and materials, thus avoiding contamination to the materials. It also has many advantages during production: compact andsimple structure and reasonable layout. These advantages can lead to betterdrying effects and higher heat exchange rate between material and hot air.

The indirect heat dryer adopts the method to transfer heat indirectly through the inscribed pipelines, which could avoid direct contact between materials and hot air. This method is suitable for drying some food, chemical materials and some materials vulnerable to pollution. The inscribed pipelines mainly adopt the stainless steel materials. This kind of dryer is 20%-30% higher in cost than the common drum dryer.

Main Features of Indirect Heating Dryer

1. The indirect heat transferdryer is 1/6 of the dryer imported from abroad in economic drain.

2. This dryer can guarantee that the drying degree and moisture content of the material satisfies our demands.

3. The heat preserving effect of the indirect heat transfer dryer is also first-class in the world.

4. It can be fueled by coal, oil and gas, and suitable for drying block, granular and powdery materials smaller than 20mm.

5. The covering area is reduced by about 50% than that of the single drum dryer; civil investment is reduced by 50%; power consumption is reduced by 60%.

6. The final moisture content canbe regulated easily according to customers' demands.

7. Low discharging temperature helps the dust removing equipment have a long service life.

8. The most important feature is that the current indirect heating dryer is driven by the riding wheel, saving a lot of labor.

Related Products

What Can I Do For You?

You can also send a message to us by this email info@sinoftm.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!

What Can I Do For You?

You can also send a message to us by this email info@sinoftm.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!