During the production process of sand dryer, customers will encounter a variety of situations, for example, the dust problem of sand dryer. The existence of dust has not only affected the health of workers, do harm to the environment, but also influenced the yield of sand dryer. Then Fote Machinery will put forward two dust removal methods for you:

For the drying flow of sand, the dust removal systems provided by Fote Machinery are the cyclone dust removal method and water dust removal method, which can be used separately or together, customers can choose any one according to their actual conditions.

1. The cyclone dust collector. It is relatively expensive, but the dust removal effect is very significant. Fote Machinery has made effective improvement of cyclone dust collector according to the characteristics and operation process of sand drying machine. The dust concentration has been reduced to a minimum amount, and it is the ideal equipment for dust removal.

2. Water dust removal method. This kind of dust removal method has low cost, but the effect is not as good as the cyclone dust collector. If the local environmental requirement is relatively low, customers can adopt this method, it only needs to build a large water pool.

In a word, the two kinds of dust removal methods can fully guarantee that the dust will be reduced to a minimum amount, so as to improve the work efficiency and yield of sand dryer as well as reduce the production cost. Actually, the best dust removal effect is the combination of the two. Fote Machinery can offer professional personnel to guide the installation, so as to achieve the best removal effect for customers.

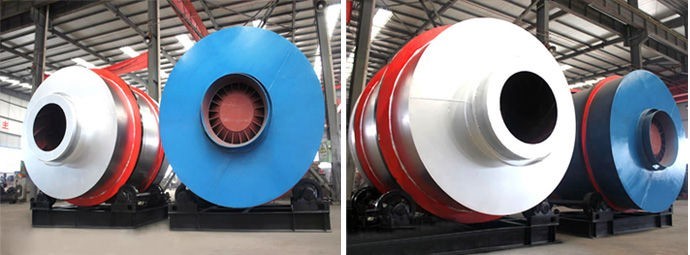

Fote Machinery is professional in R & D of drying equipment, and there are sand dryer, manure dryer, drum dryer, sawdust drying machines and other equipment. During the design and manufacturing of sand dryer, Fote Machinery is cautious in purchasing the components of the dryer to ensure its duration and reduce costs for customers.